Hordhac chip darawalka LED

iyada oo horumarka degdega ah ee warshadaha elektiroonigga ah ee baabuurta, jajabyada darawallada LED-ga cufnaanta sare leh oo leh kala duwanaansho koronto oo ballaadhan ayaa si ballaaran loogu isticmaalaa nalalka baabuurta, oo ay ku jiraan nalka hore iyo gadaal, nalka gudaha iyo muujinta iftiinka dambe.

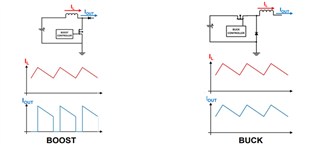

Chips darawalka LED-ka waxaa loo qaybin karaa dimming analoog iyo PWM dimming iyadoo loo eegayo habka khafiifinta.Dimming Analog waa mid fudud, PWM dimming waa mid aad u adag, laakiin kala duwanaanshiyaha toosan ayaa ka weyn dimming analoogga.Chip darawalka LED-ka oo ah heer ka mid ah chip maaraynta awooda, topology-ga inta badan Buck iyo Boost.wax soo saarka wareegga wareegga hadda si joogto ah si ay wax soo saarkeeda hadda u yar yahay, oo u baahan awood yar oo wax soo saar ah, oo aad waxtar u leh si loo gaaro cufnaanta awoodda sare ee wareegga.

Jaantuska 1 Soosaarka Kobcinta Hadda vs Buck

Jaantuska 1 Soosaarka Kobcinta Hadda vs Buck

Hababka kantaroolka caadiga ah ee chips darawalka LED-ku waa qaabka hadda (CM), COFT (waqtiga-xiran ee la kantaroolo), COFT & PCM (qaabka hadda ugu sarreeya).Marka la barbar dhigo kantaroolka qaabka hadda jira, habka xakamaynta COFT uma baahna magdhow loop, kaas oo ku habboon hagaajinta cufnaanta awoodda, iyada oo la helayo jawaab celin firfircoon oo degdeg ah.

Si ka duwan hababka kale ee kantaroolka, qaabka xakamaynta COFT wuxuu leeyahay pin COFF gaar ah oo loogu talagalay dejinta wakhtiga ka baxsan.Maqaalkani wuxuu soo bandhigayaa qaabeynta iyo taxaddarrada wareegga dibedda ee COFF oo ku saleysan COFT-ku-koontaroolka caadiga ah ee Buck LED chip darawalka.

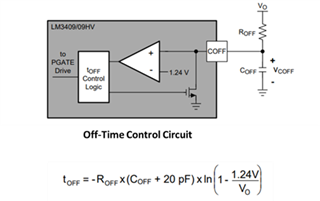

Qaabeynta aasaasiga ah ee COFF iyo taxaddarrada

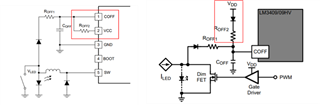

Mabda'a kantaroolka ee habka COFT ayaa ah in marka inductor-ku uu gaaro heerka hadda la dejiyay, tuubada sare waa danmaysaa tuubada hoosena waa shid.Marka wakhtiga damintu gaadho tOFF, tuubada sare ayaa mar kale shid.Ka dib marka tuubada sare ay dansato, waxa ay ahaan doontaa mid dansan wakhti joogto ah (t OFF).tOFF waxaa dejiya capacitor (COFF) iyo danab wax soo saar (Vo) oo ku yaala hareeraha wareegga.Tan waxaa lagu muujiyey Jaantuska 2. Sababtoo ah ILED si adag ayaa loo habeeyey, Vo wuxuu ahaan doonaa mid joogto ah oo ka badan tiro balaadhan oo ah koronto gelin iyo heerkul, taasoo keentay tOFF ku dhawaad joogto ah, kaas oo lagu xisaabin karo iyadoo la isticmaalayo Vo.

Jaantuska 2. wareegga kontoroolka wakhtiga ka baxsan iyo qaacidada xisaabinta ee TOFF

Jaantuska 2. wareegga kontoroolka wakhtiga ka baxsan iyo qaacidada xisaabinta ee TOFF

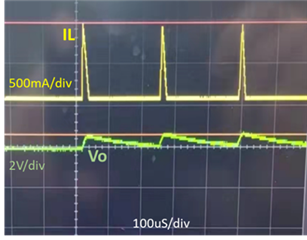

Waa in la ogaadaa in marka habka dimming ee la doortay ama wareegga dimming ay u baahan yihiin wax soo saar gaaban, wareeggu si fiican uma bilaabi doono waqtigan.Waqtigan xaadirka ah, ripple inductor hadda wuu weynaadaa, danab wax soo saarku wuxuu noqonayaa mid aad u hooseeya, oo aad uga yar danab go'an.Marka fashilkan uu dhaco, inductor-ka hadda socda wuxuu la shaqayn doonaa wakhtiga ugu badan ee fasaxa.Caadiyan wakhtiga ugu badan ee lagu dejiyay chip-ku wuxuu gaaraa 200us ~ 300us.Waqtigaan inductor-ka hadda iyo korantada wax soo saarku waxay u muuqdaan inay galaan qaab hiccup oo aan si caadi ah u soo bixin karin.Jaantuska 3 waxa uu tusinayaa qaabka aan caadiga ahayn ee mowjadaha inductor ee hadda jira iyo danab soo-saarka TPS92515-Q1 marka shunt resistor loo isticmaalo culeyska.

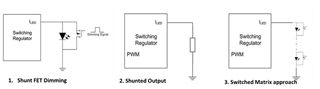

Jaantuska 4 wuxuu muujinayaa saddex nooc oo wareegyo ah oo sababi kara cilladaha kore.Marka shunt FET loo isticmaalo dhimista, iska caabiyaha shunt ayaa loo doortaa culeyska, culeyskuna waa wareegga wareegga matrixka LED, dhammaantood waxaa laga yaabaa inay soo gaabiyaan tamarta wax soo saarka oo ay ka hortagaan bilawga caadiga ah.

Jaantuska 3 TPS92515-Q1 Inductor Hadda iyo Korantada Soo-saarka

Jaantuska 3 TPS92515-Q1 Inductor Hadda iyo Korantada Soo-saarka

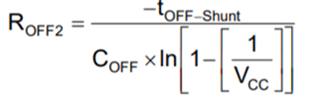

Jaantuska 4. Wareegyada laga yaabo inay keenaan surwaal gaaban

Si taas looga fogaado, xitaa marka wax soo saarka la gaabiyo, koronto dheeraad ah ayaa weli loo baahan yahay si loo dallaco COFF.Sahayda barbar socota ee VCC/VDD loo isticmaali karo sidii ay u dallaci lahayd capacitors COFF, waxay ilaalisaa waqti xasiloon, oo waxay ilaalisaa qulqulo joogto ah.Macaamiishu waxay kaydsan karaan iska caabin ROFF2 inta u dhaxaysa VCC/VDD iyo COFF marka ay naqshadeynayaan wareegga, sida ku cad Jaantuska 5, si loo fududeeyo shaqada qaladka dambe.Isla mar ahaantaana, xaashida xogta chip TI inta badan waxay bixisaa qaacidada xisaabinta ee ROFF2 ee gaarka ah iyadoo loo eegayo wareegga gudaha ee chip si loo fududeeyo doorashada macaamilka ee iska caabinta.

Jaantuska 5. SHUNT FET Dibadda ROFF2 Wareegga Hagaajinta

Jaantuska 5. SHUNT FET Dibadda ROFF2 Wareegga Hagaajinta

Qaadashada khaladka soo-saarka wareegga-gaaban ee TPS92515-Q1 ee Jaantuska 3 tusaale ahaan, habka wax laga beddelay ee Jaantuska 5 waxa loo isticmaalaa in lagu daro ROFF2 inta u dhaxaysa VCC iyo COFF si loogu dallaco COFF.

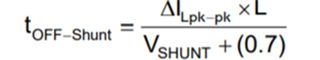

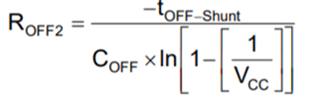

Doorashada ROFF2 waa nidaam laba-tallaabo ah.Talaabada ugu horeysa waa in la xisaabiyo wakhtiga xidhitaanka loo baahan yahay (tOFF-Shunt) marka shunt resistor loo isticmaalo wax soo saarka, halkaas oo VSHUNT waa danab wax soo saarka marka shunt resistor loo isticmaalo load.

Talaabada labaad waa in la isticmaalo tOFF-Shunt si loo xisaabiyo ROFF2, taas oo ah kharashka VCC ilaa COFF iyada oo loo marayo ROFF2, loo xisaabiyo sida soo socota.

Talaabada labaad waa in la isticmaalo tOFF-Shunt si loo xisaabiyo ROFF2, taas oo ah kharashka VCC ilaa COFF iyada oo loo marayo ROFF2, loo xisaabiyo sida soo socota.

Iyada oo ku saleysan xisaabinta, dooro qiimaha ROFF2 ee ku habboon (50k Ohm) oo ku xidh ROFF2 inta u dhaxaysa VCC iyo COFF kiiska qaladka ee Jaantuska 3, marka wax soo saarka wareegga uu yahay mid caadi ah.Sidoo kale ogow in ROFF2 uu aad uga weyn yahay ROFF1;haddii ay aad u hooseyso, TPS92515-Q1 waxay la kulmi doontaa dhibaatooyinka wakhtiga ugu yar ee shid, taas oo keeni doonta korodhka hadda iyo dhaawaca suurtagalka ah ee qalabka chip.

Iyada oo ku saleysan xisaabinta, dooro qiimaha ROFF2 ee ku habboon (50k Ohm) oo ku xidh ROFF2 inta u dhaxaysa VCC iyo COFF kiiska qaladka ee Jaantuska 3, marka wax soo saarka wareegga uu yahay mid caadi ah.Sidoo kale ogow in ROFF2 uu aad uga weyn yahay ROFF1;haddii ay aad u hooseyso, TPS92515-Q1 waxay la kulmi doontaa dhibaatooyinka wakhtiga ugu yar ee shid, taas oo keeni doonta korodhka hadda iyo dhaawaca suurtagalka ah ee qalabka chip.

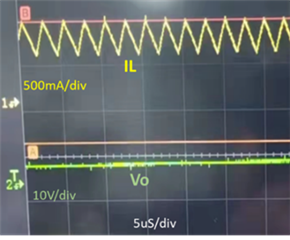

Jaantus 6. TPS92515-Q1 inductor inductor hadda iyo danab wax soo saarka (caadi ka dib marka lagu daro ROFF2)

Jaantus 6. TPS92515-Q1 inductor inductor hadda iyo danab wax soo saarka (caadi ka dib marka lagu daro ROFF2)

Waqtiga boostada: Febraayo-15-2022